- A planned maintenance system helps ships run safely, avoid breakdowns, and save costs. Learn how to use it and why it matters.

What is a Planned Maintenance System?

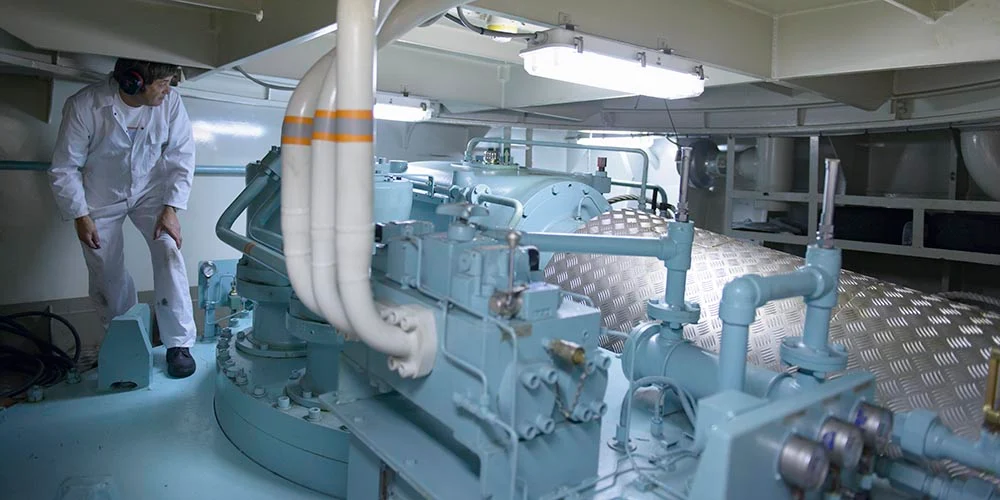

A planned maintenance system is a system used on ships to take care of machines before they break down. It works by giving tasks to the crew at the right time. These consist of examining parts, cleaning, swapping out, or fixing equipment. The system helps the crew follow a plan. They know what job to do, when to do it, and how to do it. This keeps the ship safe and working well. Small issues could become major ones in the absence of this system.

How a Planned Maintenance System Works on Ships

Every modern ship needs a good planned maintenance system. Today, ships use planned maintenance system software to make things easier. This software stores all the data about ship machinery. It sets reminders for jobs like oil changes, filter cleaning, or pump testing. Owners must first install the software before a planned maintenance system can be implemented on board. Then, they upload equipment details, manuals, and job schedules. The system then creates maintenance tasks based on hours or dates. For example, the system will send a message to verify a generator that has ran for 500 hours. Ships can avoid delays and issues at sea by using this technique. The crew stays ready and informed. Everything runs in a planned and smart way.

Key Features of Maintenance System Software

A strong planned maintenance system software supports the crew by organizing and simplifying routine tasks. It provides clear schedules that show what needs to be done and when. The system also sends alerts before each task is due, keeping the crew prepared. It stores job records, helping everyone track which tasks were completed and which are still pending. It monitors spare part levels to ensure that the right materials are always available. Detailed reports are generated for audits and inspections, making it easier to prove compliance and system care. Much like in advanced space systems, where regular upgrades are key to performance such as in Upgradable Satellites with Katalyst Space Technologies ships also rely on planned maintenance to avoid failures and stay efficient. These features make daily operations smoother, safer, and more reliable.

Benefits of Using a Planned Maintenance System

There are many advantages of a planned maintenance system on ships. Below are the top ones:

1. More Safety

With a planned maintenance system, ships stay in good condition. Important systems like engines, pumps, and safety tools work better when they are cared for on time. This reduces the possibility of malfunctions or mishaps.

2. Lower Repair Costs

Doing regular maintenance is cheaper than fixing broken parts. It can cost thousands of dollars if a ship’s engine fails. But if the engine is checked and cleaned on time, it can keep running without issues.

3. Better Planning and Time Saving

The crew knows their work in advance. The planned maintenance system software tells them what to do each day. This helps save time. There is no confusion or rush. Everything goes step by step.

4. Easy for Inspections

All ships face checks by port officials or safety groups. When ships use this system, all records are ready. This helps pass inspections without stress. Reports from the software show that work was done correctly and on time.

5. Longer Equipment Life

If a machine is cleaned, oiled, and tested regularly, it lasts longer. That means ship owners save money by not buying new parts often. A planned maintenance system helps avoid waste and keeps tools working longer.

6. Fewer Emergency Repairs

With the system in place, surprises are fewer. The software shows jobs that are coming soon. The crew stays ready. Fewer emergency jobs mean smoother sailing.

Using Software Instead of Manual Logs

Old ships used books and paper to write down tasks. This method had many problems. Sometimes tasks were missed or done late. Also, tracking work was hard. Now, planned maintenance system software fixes all these problems. It sends alerts and updates. It can be used by both the ship and land offices. Everyone stays informed. Reports are just one click away.

How to Implement Planned Maintenance System on Ship

To implement a planned maintenance system on ship, follow these simple steps:

- Pick the right software: Choose one that fits your ship and crew size.

- Enter equipment info: Add all machines, their manuals, and maker data.

- Create job tasks: Set tasks based on time or usage.

- Train the crew: Teach them how to use the software daily.

- Start using the system: Begin doing jobs as per the schedule.

Update often: If new machines are added, enter them in the system.

Your ship will be safer and more organized if you follow these procedures.

What Makes a Good Planned Maintenance System

A good planned maintenance system is easy to use. It should work even when there’s no internet. It must allow reports, set clear tasks, and give alerts. The best planned maintenance system software also links with land offices. This facilitates real-time task tracking for ship owners. If a ship misses a task, they get notified.

Real Examples from Ships

Large tankers, cruise liners, and container ships all use these systems today. The system monitors more than 600 tasks on some large ships. Engine maintenance, cooling system inspections, safety alerts, and even kitchen appliances are among them. By using a planned maintenance system, many ships have reduced repair costs, passed audits easily, and stayed on schedule.

Challenges to Watch

Even with good software, problems can happen. If crew members skip tasks or enter wrong data, the system will not work well. Additionally, software may be difficult for some older crew members to utilize. That’s why training is important. Shipowners should also back up data regularly. If a computer crashes, all records must still be safe.

Future of Maintenance Systems at Sea

New versions of planned maintenance system software now use sensors and smart tools. They can read real-time data from machines and detect faults early. These systems use AI to predict equipment failures before they happen, enabling timely fixes and preventing expensive disruptions. Cloud integration allows ship data to be shared with land offices in real time. This helps managers make better decisions and keep ships on schedule. According to SBN Tech, such predictive tools enhance efficiency, improve safety, and reduce maintenance costs across entire fleets

Final Thoughts

A planned maintenance system is very useful for ships today. It helps avoid breakdowns, saves money, and makes work easy. With the help of planned maintenance system software, the crew can follow tasks, record jobs, and stay ready. To implement a planned maintenance system on ship is simple if done step by step. The advantages of planned maintenance system on ships are clear, fewer repairs, better safety, and smooth sailing. Every ship that wants to stay ahead must use this system. It is not just a tool. It is a smart way to run a ship.